Aluminum die casting custom design parts

Diecast Custom Parts,Custom die cast components service

Different components have different technical request, such as tolerances request, mechanical property request, also with surface request. Like salt spray testing and scratch prevent methods. many components will assemble with another metal parts together, so how can we prevent any potential problem in assemble line when products delivery to customer factory. So reading drawing careful before quote will much better.

Custom Die Casting - At Goal Sure, We can help with your ideas!

While the initial cost of a die-cast part is higher compared to some casting methods, it tends to reduce the unit cost of high-volume production. Other benefits include smooth surface finishes, durable products and a reduced need for certain secondary machining processes.

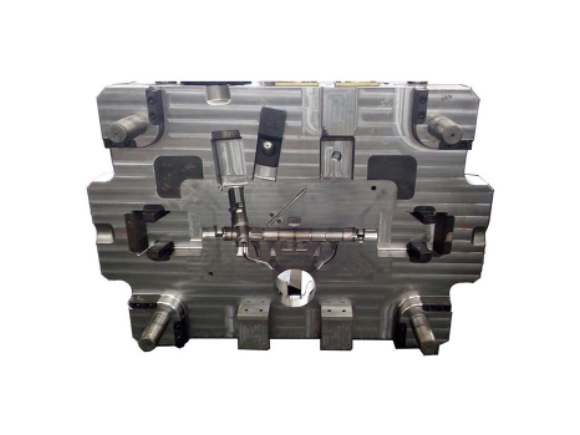

The process involves multiple steps. The first step is the creation of a mold. Molds are created based on prototypes or patterns that allow for rapid production of identical parts. During production, the mold is prepared with lubricant, which helps control the temperature while making it easier to remove the casting. Two half molds are pressed together. The molten metal is then pressed into the cavity created by the mold. After the casting has solidified, the mold is opened and the part is ejected.

Custom Die Casting

Die casting is a manufacturing process that utilizes reusable molds or dies to mass produce complex metal parts at a competitive cost. The process occurs in a highly automated facility and involves the use of four key elements: raw metal, furnaces, molds and die casting machines. The metals used in the die casting process are typically non-ferrous alloys of aluminum, brass, zinc or copper, but the composition of the alloys used may vary, depending on individual customer specifications and product requirements.

During the production process, the metal is melted in either a cold chamber or hot chamber furnace. Cold chamber furnaces are used for high melting point metals or metal alloys, such as aluminum, while hot chambers are used for low melting point metals or metal alloys, such as zinc. Once the metal is in the liquid state, the die casting machine forces it into the mold, where it will quickly cool and solidify into the desired shape.

Because it is almost completely automated, the die casting process has very low labor costs. However, the costs involved in tool steel die production and the use of complex heat resistant tools require high volume production to achieve relatively low unit costs.

Mechanical properties and applications of die castings

The versatility of die casting makes the process well suited for the manufacture of many types of die cast parts that display a range of different textures on their surfaces. These parts can come in a variety of sizes and weights, from parts weighing only a few ounces to large parts weighing hundreds of pounds.

Regardless of size, all die cast parts display very fine grain size and good mechanical properties, including dimensional stability, durability and dimensional accuracy. In addition, because die cast parts do not consist of separate components welded or otherwise held together, their strength is not limited by the strength of the welds, but depends entirely on the strength of the materials they are made of.

Because of their versatility and relatively low cost, die castings have found application in many industries. They are particularly widely used in the automotive industry as engine blocks, pistons and cylinder heads, but they also often form components of consumer appliances and equipment. Other industrial applications include gears, pumps, propellers, valves, electrical housings and enclosures, bushings, valves, etc.

Die Cast Metals and Alloys

The die casting process typically uses aluminum alloys, copper alloys, magnesium alloys, and zinc alloys. The choice of a particular alloy depends on the physical properties and design characteristics required for the final casting. Qualities such as corrosion resistance, melting point, density and strength may influence this decision, along with cost considerations.

Each metal used has specific properties that may prove advantageous in some cases. For example, aluminum alloys typically offer advantages such as light weight and corrosion resistance. In contrast, copper alloys are typically more costly, but offer excellent electrical conductivity.

The desired part design characteristics may also strongly influence the choice of materials used for die-cast parts. Some metal alloys, such as zinc, show high ductility, and these alloys may be excellent choices for parts with better surface finishes and thin walls.

The choice of material can also affect the machining and processing possibilities. While zinc and other alloys that melt at low temperatures are cast using hot chamber machines, aluminum and copper alloys with significantly higher melting points require the use of cold chamber machines.

Advantages of Using Die Casting

The die casting process offers many manufacturing advantages. Unlike other casting methods, it allows for the mass production of very complex shapes with multiple chambers and thin walls. Due to corrosion resistance rates ranging from good to high, die-cast surfaces can remain in the cast condition without the need for protective finishing. However, if necessary, there are many surface treatment options available, including acid etching, anodizing, painting, electroplating and powder coating finishes.

The mold used in die casting is a semi-permanent mold that can be used to produce thousands of identical parts. The die will eventually need to be replaced, reworked or machined, a consideration that is typically incorporated into the cost projections associated with the die casting process. However, die casting remains cost effective and efficient because of the ability to produce a large number of parts using a single mold.

Hot Chamber vs. Cold Chamber Die Casting

We use two types of die casting machines. Depending on the material and time frame, we can use either a hot chamber machine or a cold chamber machine.

The hot chamber system relies on a piston to press the molten metal into the mold. This machine has a built-in furnace to heat the metal. A hydraulically driven piston then pushes the metal into the mold at a rapid rate, with a typical cycle lasting only about 15 minutes.

The cold chamber system includes an additional step in the process. Instead of a built-in furnace, these machines require a separate furnace to melt the metal.

An injection cylinder is used to transfer the molten metal into the machine. The cylinder uses a piston to squeeze the metal into the mold. The additional step of transferring the molten metal increases the production cycle time.

The main advantage of cold chamber casting is the ability to handle a wider range of metals. Metals with high melting points require the use of a separate furnace, which is not an option for hot chamber systems.

Cold chamber casting is best suited for materials such as brass, steel, copper, nickel, iron, and occasionally aluminum. Hot chamber casting offers an effective solution for tin, zinc and alloys with lower melting points.

Sand Casting and Die Casting

While die casting relies on high pressure to press liquid metal into a mold, sand casting involves pouring liquid metal into the mold.

The sand casting process involves pressing a mixture of sand and clay into a box called a flask. Model parts are placed in the mixture to create a mold. Molten metal is poured into the mold to form the desired shape.

As the metal cools, the sand is blown away. Our sand casting process produces high quality parts with minimal porosity and defects compared to die casting. Sand castings are also suitable for a wider range of materials.

Although we offer alloy die casting services, die castings are not suitable for all materials. Sand castings can be made from a variety of ferrous and non-ferrous alloys. Sand casting, however, is a more detailed process.

If you have a short product development cycle time frame, die casting is the preferred choice. Our die casting services include quick turnaround for most projects.

Metal Stamping and Die Casting

Metal stamping is another service we offer for manufacturing quality parts. Our stamping equipment allows us to use steels and alloys that may not be suitable for the die casting process.

For simple parts and quick production, stamping is preferred. However, this process usually involves fewer components and assembly operations and a closer final shape.

Investment Casting vs. Die Casting

Investment casting is another casting process offered by Goal Sure. With our investment casting service, we can create wax patterns from master molds. The wax pattern is coated with a final hardened ceramic material.

The wax is then melted, leaving an empty ceramic mold. This process allows for very complex designs and higher precision than die-cast parts.

Although investment casting requires less tooling, the unit price is usually higher. It is also a more time consuming process.

Finally, die casting is the preferred choice for a wide range of applications. It is still one of the most efficient casting processes, especially for high volume production. Depending on your specific project, little or no machining is required.

High-pressure casting and gravity casting

At Goal Sure, we also offer high-pressure casting and gravity casting depending on the project requirements.

Gravity casting is typically used for heavy products and high volume production. It relies on gravity to allow the natural flow of molten metal into the mold cavity. Compared to sand casting, this process is more suitable for projects requiring thin walls or smooth surfaces.

In addition to gravity casting machines, Goal Sure has a variety of high pressure die casting machines. These machines allow for quick turnaround due to shorter casting cycles.

Our responsibility to let customer to know which kind aluminum alloy will most fit for their components character, different aluminum alloy have different mechanical property, some alloy have good corrosion resistant, some alloy strength than another one, some alloy fit for auto components, some alloy will have good cosmetic surface after finishing, particularly for chrome finishing aluminum die casting parts. Such as Which production process will make components superior standard, how can we solved cost for custom project. This is benefit each other. Anyway the fine die casting solutions will get more inquiry.

For example with one item production, structure of sofa leg is quite simply for most high pressure aluminum injection factory, does all of aluminum die casting factory has impact simulation software and testing facility? just suppose 100kg person jump to sofa. Impact at least 500kg. so your sofa leg impact resistant capability at least 800kg. how can we make die casting sofa leg strength and durable? no recycle material allowances, of course the strong aluminum injection tools is necessary. But we still need careful when we order the products from poor facility aluminum alloy die casting company. die casting chair leg manufactory will reduce cost by small size machine to casting big one, how can they prevent deformation problem? just leave item in mold cavity more one minute, even no any air porosity problem when testing by x-ray. But actually this is very high risk for purchaser.

The ageing problem will very seriously when products get to much heat from mold cavity, all die cast manufactory knew how to prevent overheat problem during casting