Home > News > Ways To Improve Aluminum Die Casting Part Quality

Ways To Improve Aluminum Die Casting Part Quality

Aluminum is recognized for its lightweight and durability and is one of the most popular materials used in the production of functional parts and prototypes. It also has impeccable corrosion resistance, thermal conductivity, and electrical conductivity, and can maintain dimensional stability even in high temperatures and harsh environments.

Because this special metal has such a high melting point, the best way to cast aluminum parts is to use an aluminum die casting process.

Aluminum dies casting reduces the steps required for production and prototyping, ultimately reducing manufacturing costs, while also providing parts with a high-quality surface finish and extraordinary dimensional consistency. This technology has particular advantages in small and medium-sized castings and is widely used in industries such as automobiles, aerospace, and medical.

Understand all design aspects and geometric features

Before designers or engineers can make full use of aluminum die-casting technology, it is important that they first understand the design limitations and common geometric features that this manufacturing technology can achieve. Here are some factors that you should keep in mind when designing aluminum die casting parts.

Draft-In aluminum dies casting, the draft is considered to be the slope to the core or other parts of the cavity, which makes the casting easier to eject from the mold. If your die casting is parallel to the opening direction of the mold, the draft is a necessary supplement to your die casting design. If you optimize and implement a proper draft, it will be easier to remove aluminum die casting from the die, increase precision and result in a higher quality surface.

Fillet-A fillet is a curved seam between two surfaces that can be added to your aluminum die-casting to eliminate sharp edges and corners.

The parting line-The parting line is the point where the two different sides of the aluminum die casting mold are joined together. The parting line position represents one side of the mold, which is used as a cover and is used as an ejector.

Bosses-When adding bosses to aluminum die casting, these will be part of the mounting point and will need to be installed later. In order to optimize the integrity and strength of the bosses, they should have the same wall thickness throughout the casting.

Ribs-Adding ribs to aluminum die castings can provide more support for designs that require maximum strength while maintaining the same wall thickness.

Holes-If you need to add holes or windows to your aluminum die casting mold, you need to consider the fact that these features will adhere to the mold steel during solidification. To overcome this problem, designers should integrate generous drafts into the functions of holes and windows.

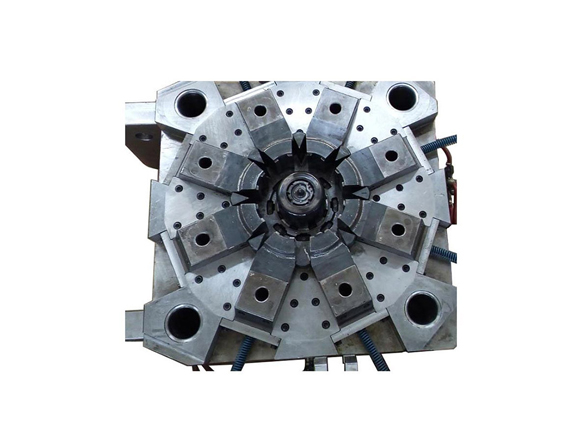

Aluminum Die Casting Mold

Understand the service life of aluminum die casting molds and tooling

If you think aluminum die-casting is the right choice for your production needs, you should understand the life and maintenance required for aluminum die-casting molds. The life of a mold is difficult to determine because it depends heavily on many factors. You need to keep in mind many aspects, including the design of the part, the tool steel used in the mold, the mold configuration, heat treatment, the aluminum alloy used, the desired part quality, and so on.

Using heat treatment technology to extend the service life of aluminum die casting molds

One of the best ways to extend the life of aluminum die-casting molds is to use heat treatment and die coatings. Through the application of these technologies, thermal inspection will be greatly slowed down, ultimately extending the life of the tooling. Of course, you must consider the additional cost of these coatings and decide whether it is worthwhile to extend the life of aluminum die-casting molds.

When it comes to heat treatment, there are some very important aspects to consider, such as the heat treatment furnace used, the number of tempering used for the module, and the quenching rate used in the heat treatment process.

We are aluminum die casting molds suppliers. Please feel free to contact us if you need or want to know about our products.